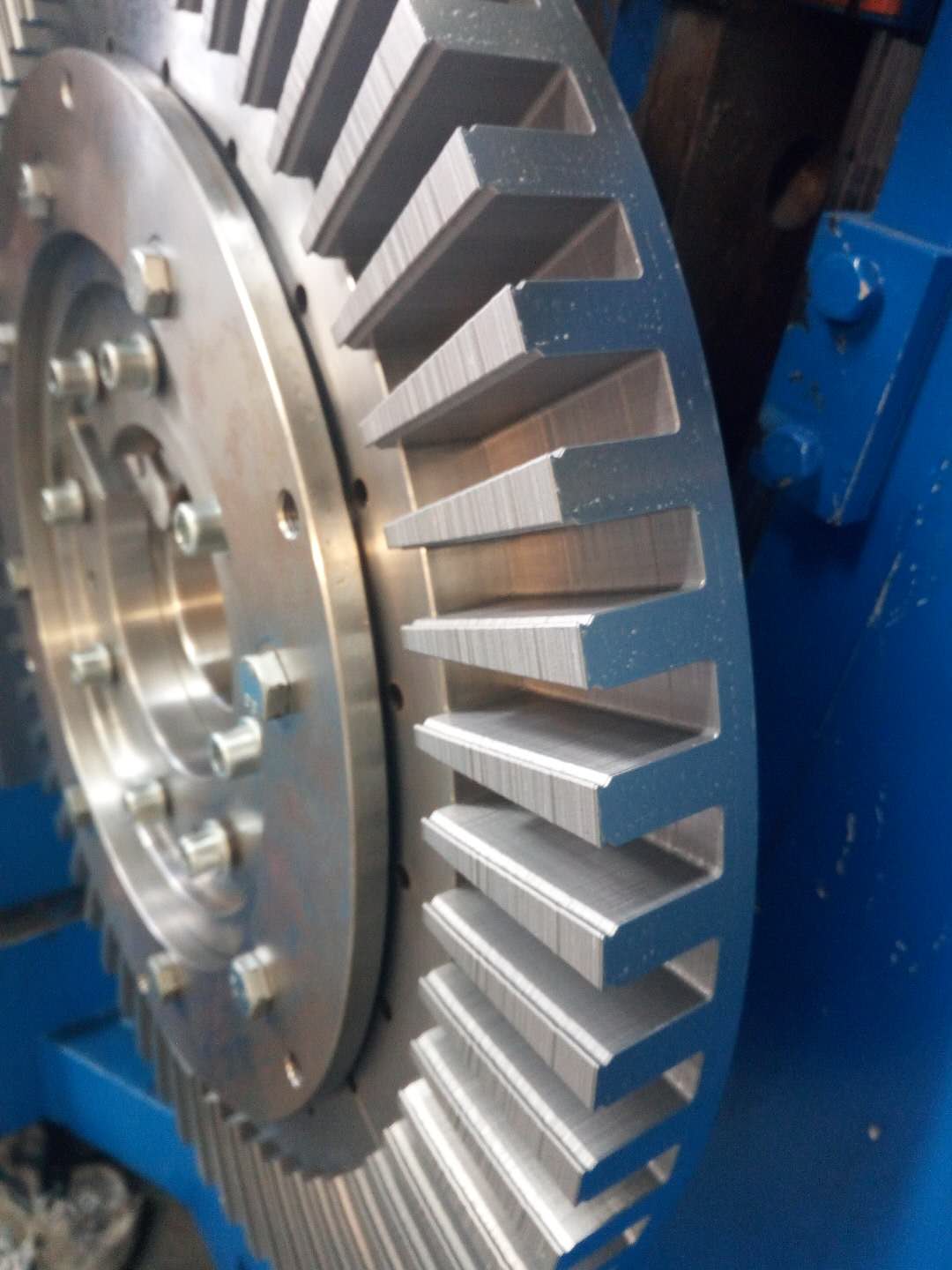

On 17th June year 2017, the second iron-core punching machine completed adjustment successfully. It indicates the project of iron-core Rolling of Day Power disc motor and has started mass production.

The technology of iron-core Rolling in disc motor is grasped by few suppliers in home market before. With the hard working of Day Power’s researching team, we finally have achieved a breakthrough in this technology after more than four-month hard work in research and many times in testing at site. We make the iron core of the stator as much as perfect with our technology advantage. On the level of technology, we have reached an advanced level. And now Day Power iron core stator has covered 7 specifications of our disc motors.

Now the production of stator of Day Power disc motor has completed the full manufacturing process from iron-core Rolling, robot welding, auto routing, embedding, vacuum dipping paint, to automatic drying(as figure 2). At the same time, the key part of Day Power disc motor has completed the full manufacturing process. The overcome of iron-core Rolling technology means a lot to the strategic development of Day Power. It indicates the hi-tec and quality of Day Power disc motor and takes an important step towards the goal of becoming the leader in elevator motor and drive industry.

Position:

Position: